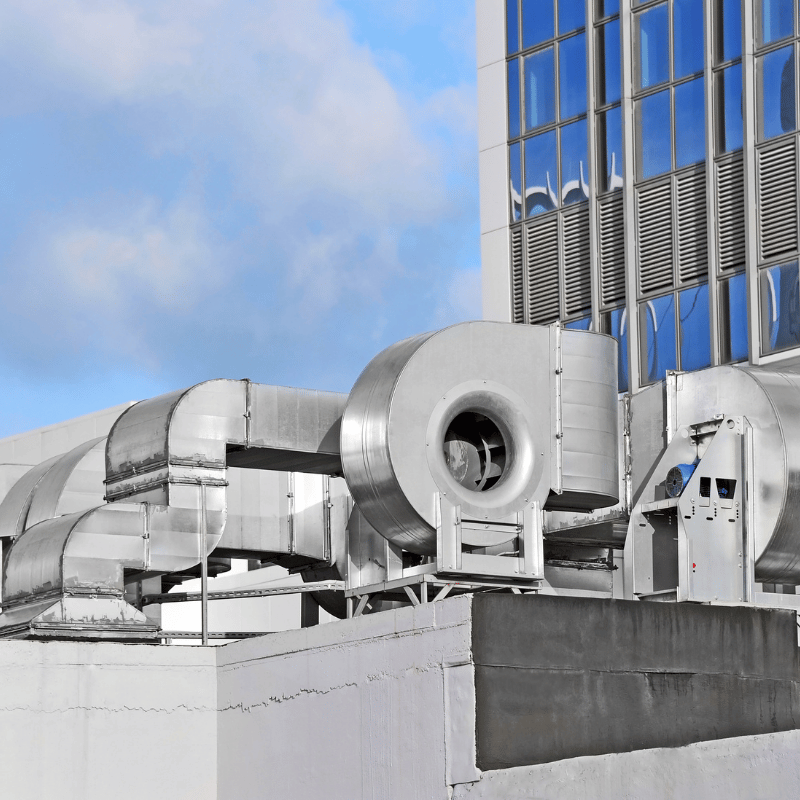

Ventilation Systems for Industrial and Manufacturing Facilities in Ireland

Custom ventilation and extraction solutions designed for industrial environments, ensuring compliance, safety, and operational efficiency.

Ventilation for Industrial and Manufacturing Environments

Industrial and manufacturing settings demand robust, high-performance ventilation systems that can handle heavy workloads, airborne contaminants, and strict compliance requirements. At Mor-Air Mechanical, we design and install systems that are built to perform under pressure, whether you’re operating a busy warehouse, a fabrication plant, or a processing facility.

Our team brings deep experience across a wide range of industrial sectors, delivering tailored HVAC and extraction systems that prioritise airflow, filtration, and air quality. We also account for heat output, moisture control, and emissions, ensuring your workplace is comfortable, compliant, and safe for your team.

Whether you’re retrofitting an existing plant or planning a new build, we provide full mechanical ventilation design, installation, and ongoing support services.

Managing Air Quality, Compliance & Worker Safety

Maintaining clean, safe air is non-negotiable in industrial and manufacturing environments. From dust and fumes to chemical byproducts, poor air quality can quickly lead to health risks, safety issues, and non-compliance with workplace regulations. Our energy-efficient ventilation systems are designed to extract harmful particles, control humidity, and ensure constant air circulation—minimising risk and maximising operational safety.

We help your business meet the latest building regulations, HSE guidelines, and environmental standards. Whether you’re operating a production floor, workshop, or large-scale facility, we install systems that protect your team and your processes. With advanced filtration and airflow control, we create working conditions that are safer, cleaner, and more productive.

📍 Explore our Servicing and Maintenance page to learn how we keep your ventilation systems running at peak performance

Ventilation Solutions Built for Performance

Every industrial and manufacturing facility comes with unique airflow challenges—high ceilings, heavy machinery, variable temperatures, and continuous output. That’s why our ventilation systems are designed with performance at their core. From robust extraction units to high-capacity ducting, we install solutions that keep air moving efficiently, even under the toughest conditions.

Our systems are engineered to support round-the-clock operations, reduce energy consumption, and maintain consistent indoor air quality across large areas. Whether you’re managing heat in a metalworks facility or controlling dust in a manufacturing plant, we ensure your environment stays productive and compliant—all while reducing long-term maintenance costs.

📌 Want to know how our systems can reduce downtime and improve efficiency? Learn more on our Custom Solutions page.

Request a Call

Frequently Asked Questions

What type of ventilation systems are best suited for manufacturing facilities?

We typically recommend high-capacity mechanical ventilation with extraction and filtration systems designed to manage heat, fumes, dust, and airborne particles common in industrial settings.

Can your systems be customised for specific machinery or processes?

Yes. We offer fully customised solutions tailored to your facility’s layout, machinery placement, and process-specific ventilation needs.

How do your systems help with workplace safety compliance?

Our systems help you meet HSA air quality regulations and health and safety standards by controlling contaminants, maintaining fresh air levels, and reducing hazardous exposure.

Do you provide maintenance services for industrial ventilation systems?

We offer full servicing and maintenance packages to ensure your systems remain compliant, energy-efficient, and operating at peak performance over time.

Can you install systems without interrupting production?

Absolutely. We work around your operational schedule to minimise downtime and ensure seamless integration with existing infrastructure.