Ventilation Systems for Pharmaceutical Facilities in Ireland

Maintain strict hygiene, air purity, and compliance standards with expertly designed ventilation solutions tailored to the needs of the pharmaceutical sector.

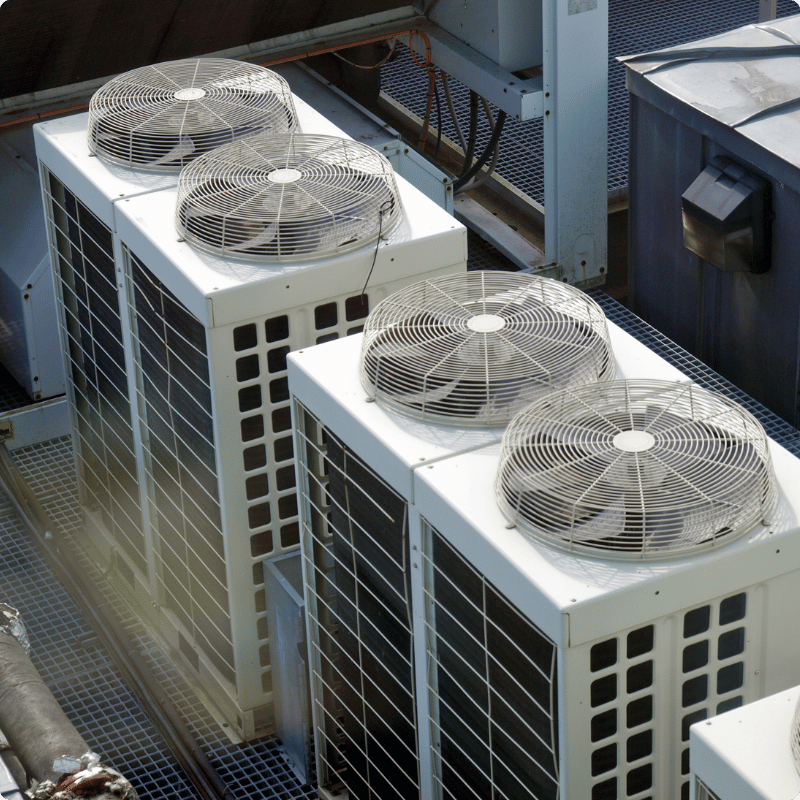

Specialist Ventilation for Cleanrooms and Critical Areas

In pharmaceutical environments, cleanrooms and controlled areas demand the highest standards in air purity and pressure control. At Mor-Air Mechanical, we understand the exacting requirements of these spaces and deliver specialist ventilation systems that support GMP compliance, minimise contamination risk, and ensure consistent airflow performance.

Our systems are designed to manage air change rates, filtration levels, humidity, and temperature with pinpoint accuracy, all while maintaining energy efficiency and reliability. Whether it’s for a new build or a retrofit project, we work closely with contractors, consultants, and facility managers to ensure your cleanroom environments are fit for purpose and future-ready.

Built for Compliance, Efficiency and Long-Term Use

Pharmaceutical facilities in Ireland must adhere to strict industry regulations, including those set by the HPRA and EU GMP guidelines. At Mor-Air Mechanical, we don’t just install ventilation systems, we ensure every system is engineered with compliance in mind from the outset.

We prioritise air quality control, particulate filtration, and temperature regulation to meet cleanroom classification standards. Our systems are rigorously tested and commissioned to perform within the specified tolerances, ensuring full traceability and documentation for audit readiness.

From initial consultation through to installation and ongoing support, we help you maintain a fully compliant environment without sacrificing operational efficiency.

Systems to Suit Every Pharmaceutical Facility

No two pharmaceutical environments are the same, from cleanrooms and production lines to research labs and packaging areas, each space has its own airflow and contamination control requirements. That’s why Mor-Air Mechanical designs and installs tailored ventilation systems built around the exact needs of your facility.

We assess the specific demands of your layout, processes, and cleanroom classifications, then create a system that supports sterile conditions, minimises cross-contamination, and integrates seamlessly with existing infrastructure. Whether you’re building a new pharma facility or upgrading an older system, we deliver scalable, energy-efficient solutions with long-term reliability.

Ready to improve air control in your pharmaceutical environment?

Request a Call

Frequently Asked Questions

Why is specialised ventilation important in pharmaceutical facilities?

Pharmaceutical environments demand precise control over air quality to prevent contamination, ensure product integrity, and comply with strict industry regulations like GMP and ISO cleanroom standards. Standard ventilation systems simply don’t offer the level of control required.

Can your systems be designed for GMP and cleanroom compliance?

Yes, all our ventilation systems can be tailored to meet GMP, ISO 14644, and cleanroom classification requirements. We take your compliance standards into account from the initial design through to final commissioning.

Do you provide solutions for both new builds and existing facilities?

Absolutely. Whether you’re planning a new facility or retrofitting an older site, we offer custom ventilation designs that integrate with your layout and operational needs.

How energy-efficient are your ventilation systems?

Energy efficiency is built into every system we design. From variable air volume systems to heat recovery ventilation, we ensure your facility maintains strict air control while minimising running costs and carbon impact.

What’s the typical turnaround for a pharmaceutical ventilation project?

Project timelines depend on the scale and complexity of the job, but we always prioritise safety, compliance, and clear communication. After our initial consultation, we’ll provide a detailed timeline with key milestones.